Expert craftsmanship serving the optical industry

With a long-standing tradition of excellence in material innovation, Mazzucchelli continues to push the boundaries of optical manufacturing. As a pioneer in the use of cellulose acetate and now committed to an eco-friendly approach, the company is redefining industry standards.

To better understand the current and future challenges of the sector, we had the opportunity to speak with Elena Orsi Mazzucchelli, Product Development Manager and a member of the founding family. In this exclusive interview, she shares how Mazzucchelli blends tradition and innovation while making sustainability a core focus of its developments.

Interview with Elena Orsi Mazzucchelli : sustainable innovation at the heart of the optical industry

Parisee -. Could you briefly explain the circumstances and the point in time when the company turned towards the optical sector? What is its current position in this sector?

Elena Orsi Mazzucchelli -.175 years ago, Santino Mazzucchelli founded a workshop to craft combs and buttons from horn, bone and tortoiseshell. Over the years, this small enterprise expanded significantly and today it stands as a global leader, renowned for its advanced expertise in manufacturing and distributing cellulose acetate granules and sheets, mainly used in the eyewear industry.

Since 1849, the company has witnessed significant transformations in products, technologies and markets, ensuring continuous growth and adaptability in the face of evolving social and economic contexts. One crucial moment came just a few decades after its establishment, with the adoption and subsequent production of celluloid, the first thermoplastic material. This innovation allowed Mazzucchelli to become a key market player by producing objects widely used in everyday life until the mid-20th century.

In 1936, the company reached a significant milestone by transitioning to the use of cellulose acetate, a material that would later become its hallmark. This shift marked a turning point, as it allowed the company to expand its expertise and explore a range of other innovative polymers, including polystyrene, ABS, methacrylate, and PVC. Each of these materials opened up new opportunities in the production of a wide variety of consumer goods, from household items to industrial applications, thus allowing Mazzucchelli’s products to reflect the changing needs of modern society, positioning the company as a versatile and innovative force in polymer processing.

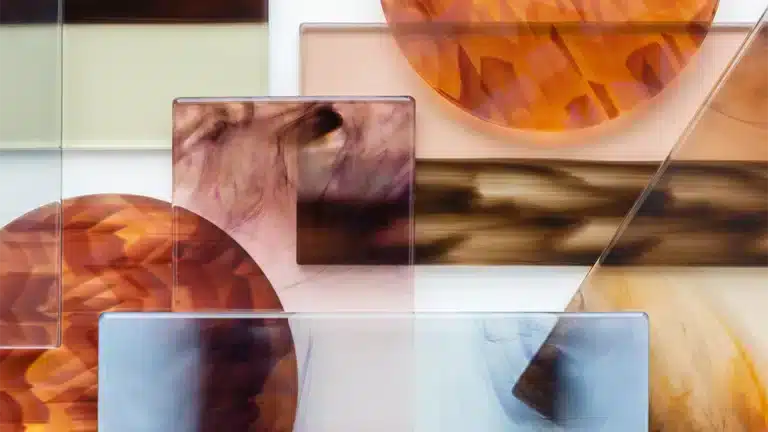

Cellulose acetate remains, nonetheless, the flagship material of the Company which, taking advantage of Mazzucchelli’s s long history and new technology, is today one of the main material for eyewear frames. Its natural origin, easy customization, durability, and design possibilities made it a perfect choice for designers and manufacturers looking to create high-quality and attractive eyewear.

This pivot not only reinforced Mazzucchelli’s reputation as a pioneer in the polymer industry but also solidified its standing as a global leader in the production of cellulose acetate for the eyewear sector. Over the decades, this material has become synonymous with premium quality, contributing to the success of countless iconic brands and establishing itself as an indispensable component in the creation of luxury and fashion-forward frames worldwide.

Parisee -. What motivated the introduction of materials like «acetate renew» or «M49 bioplastic» ?

Elena Orsi Mazzucchelli -. Mazzucchelli has always been deeply committed to sustainability, consistently investing in processes, materials, and technologies to reduce its environmental impact. The continuous pursuit of innovative solutions has led to the introduction of cutting-edge materials such as “M49 bioplastic” and “Acetate Renew”. Notably, with M49, Mazzucchelli anticipated the times by responding to and aligning with market demands even before sustainability became a widely discussed priority. The introduction of these materials was mainly driven by the eyewear industry’s increasing emphasis on sustainability and minimizing its environmental footprint. As both consumers and companies became more aware of the importance of eco-friendly alternatives, these materials emerged as innovative solutions.

Parisee -. What makes these materials unique? How are they sustainable, and what benefits do they offer compared to other materials ?

Elena Orsi Mazzucchelli -. M49, Mazzucchelli’s bioplastic, combines the mechanical properties of traditional formulations with exceptional eco-sustainability by replacing conventional plasticizers with a plant-based alternative, resulting in impressive bio-based content.

Acetate Renew uses Carbon Renewal Technology, an innovative technology developed by Eastman, to transform plastic waste into primary molecules, reducing landfill waste and creating virgin flakes for production. These innovations demonstrate sustainability by reducing environmental impact while maintaining or improving performance characteristics.

Parisee -. In your opinion, what are the future materials in the eyewear industry ?

Elena Orsi Mazzucchelli -. The industry’s future will see an even greater commitment to integrating sustainability with high performance, paving the way for materials that set new standards in both functionality and environmental responsibility. These materials will prioritize sustainability and high performance, thus reducing environmental impact while enhancing the comfort, durability, and functionality of eyewear. The focus will be on creating materials that are both eco-friendly and capable of meeting the demands of modern consumers, blending aesthetics and practicality. The result will be eyewear that reflects the values and expectations of a more conscious and discerning market.

Parisee -. Could you provide examples of collaborations with brands in the optical sector ?

Elena Orsi Mazzucchelli -. Mazzucchelli has always collaborated with a wide range of brands. Whether working with large, well-established companies or smaller, emerging brands, we approach every project with the same level of care and dedication, as we really believe that every partnership could be an opportunity for a unique experience of sharing, creativity and talent as well as a mutual exchange of knowledge and expertise.

Parisee -. What do brands specifically seek when partnering with Mazzucchelli ?

Elena Orsi Mazzucchelli -. Brands partnering with Mazzucchelli are looking for a trusted collaborator who can translate their unique identity into high-quality, customized solutions.

We understand that every brand has its own identity and we tailor our solutions to fit each one allowing us to build strong, lasting relationships with them. Our goal is to understand our customers’ vision and meet their needs thus helping them bring their ideas to life.

Parisee -. Are brands pushing you to adopt more environmentally friendly production methods and materials ?

Elena Orsi Mazzucchelli -. Over 10 years ago, we made the conscious decision to embark on a journey toward sustainability. It wasn’t driven by pressure from brands or customers, but rather by our own values and long-term vision. We recognized early on the importance of adopting more environmentally friendly production methods and materials, even before it became a widespread trend.

Parisee -. How does this demand influence your development choices ?

Elena Orsi Mazzucchelli -. Our commitment to sustainability shapes our development choices, from selecting eco-friendly materials to optimizing our production processes, ensuring that every decision aligns with our environmental goals.

Parisee -. What major challenges have you encountered during your transition to a more eco-responsible model ?

Elena Orsi Mazzucchelli -. Of course, this transition towards a more sustainable vision hasn’t been without challenges. Finding the right solutions that balance sustainability with our operational needs and ensuring that our processes align with these goals have been some of the key obstacles. Among the most significant challenges has been our ability to translate our expertise in creating unique colors and patterns into environmentally friendly materials.

The next challenge we will face is making these materials cost-competitive. The ecological transformation is currently influenced by an unfavorable global economic situation, but we are confident that this trend will shift in the long term. Despite these obstacles, we remain committed to sustainability because we believe it is essential for both the future of our business and the planet.

Parisee -. How do you maintain a balance between tradition and innovation ?

Elena Orsi Mazzucchelli -. Balancing tradition and innovation is a key focus for Mazzucchelli, particularly as it aims to evolve while staying true to its values and mission. In fact, preserving its legacy of quality craftsmanship while embracing advanced technology to refine its production processes has always been a priority.

Throughout its long history, the company has undertaken numerous activities, often diverse in nature, yet all bound by a common thread: care.

This single word encapsulates the essence of Mazzucchelli’s approach. Care for quality has always been its top priority, ensuring that every product meets the highest standards of excellence. Care for customers, whether large global brands or small independent artisans, reflects its commitment to building meaningful, lasting relationships. Care for innovation drives the company to continuously evolve, blending traditional aesthetics with modern functionality.

Parisee -. What role does Mazzucchelli play in the ecological transformation of the optical industry ?

Elena Orsi Mazzucchelli -. As a leading reference in the industry, Mazzucchelli’s choices have a strong impact, influencing not only its own future but also setting a standard for others in the sector. This solid dedication to care is what allows Mazzucchelli to honor its past, excel in the present, and shape the future.

Parisee -. Do you think the industry is ready to adopt 100% sustainable materials on a large scale? In your opinion, what is the future of materials in the eyewear industry ?

Elena Orsi Mazzucchelli -. The adoption of 100% sustainable materials on a large scale is both a strategic choice and a matter of cost. While the demand for sustainable materials is continuously growing, the transition requires a collective commitment from the entire industry. Currently, the higher production costs of eco-friendly materials can pose a challenge, but this is an investment in the future.

We believe that the eyewear industry’s future lies in materials that combine sustainability with performance and aesthetics. This evolution is not just a necessity but a reflection of the values of an increasingly conscious market.

For over 175 years, Mazzucchelli 1849 has been a key player in the optical industry, combining traditional craftsmanship with technological innovation. Today, in response to environmental challenges, the company is reinforcing its commitment by developing sustainable materials like M49 bioplastic and adopting eco-friendly processes such as Carbon Renewal Technology. This dedication to rethinking cellulose acetate production marks a major shift for the eyewear industry, providing designers and brands with solutions that are both aesthetically refined, high-performing, and environmentally responsible.

By blending tradition, innovation, and ecological responsibility, Mazzucchelli is shaping the future of optical materials and solidifying its role as a leader in the transition toward more sustainable eyewear. The industry is undergoing a profound transformation, and thanks to pioneering initiatives like those of Mazzucchelli, the future of eyewear is being defined by design, performance, and a commitment to the planet.